We engineer, install, service, and upgrade turnkey robotic automation systems.

Top Ways We Can Improve Your Bottom Line

Labor Solutions

Increased Production

Quality Improvement

Our Core Services Include:

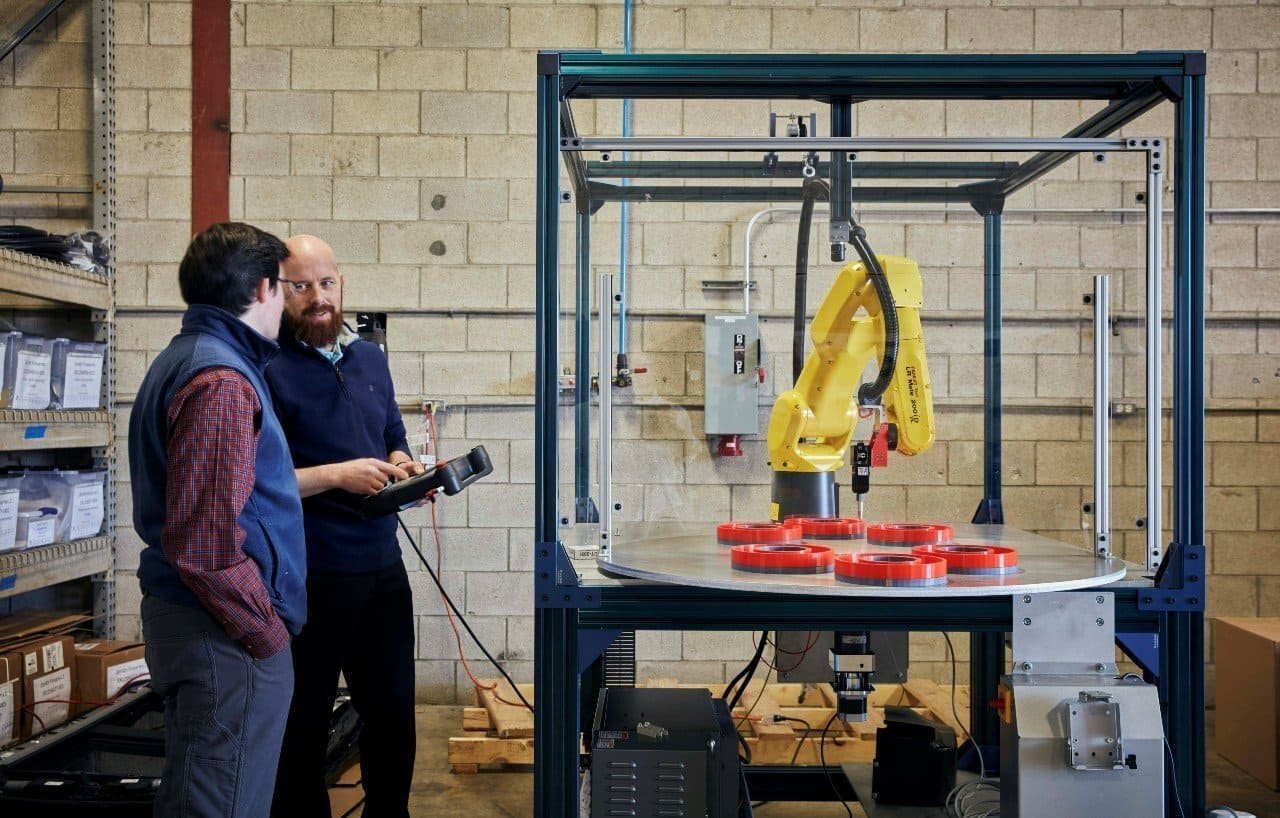

IMM Machine Tending, Injection Mold, Pick-and-Place

Robotic pick and place application that picks tape dispenser blades from a Graco G-Flex 1500 vibratory feeder using Fanuc 2D Vision. Once the Fanuc LR Mate 200iD has loaded the nests, a signal is sent to the Fanuc R1000iA to pick the blades and load into the injection mold machine. If the parts are misloaded onto the nest, the part detection sensors on the nest send a signal to the robot to remove the misloaded blade using a custom-made cylinder with a high strength magnet. This system improved the customer’s cycle time and reduced blade misloads into the injection mold machine, which allowed for more throughput and less downtime.

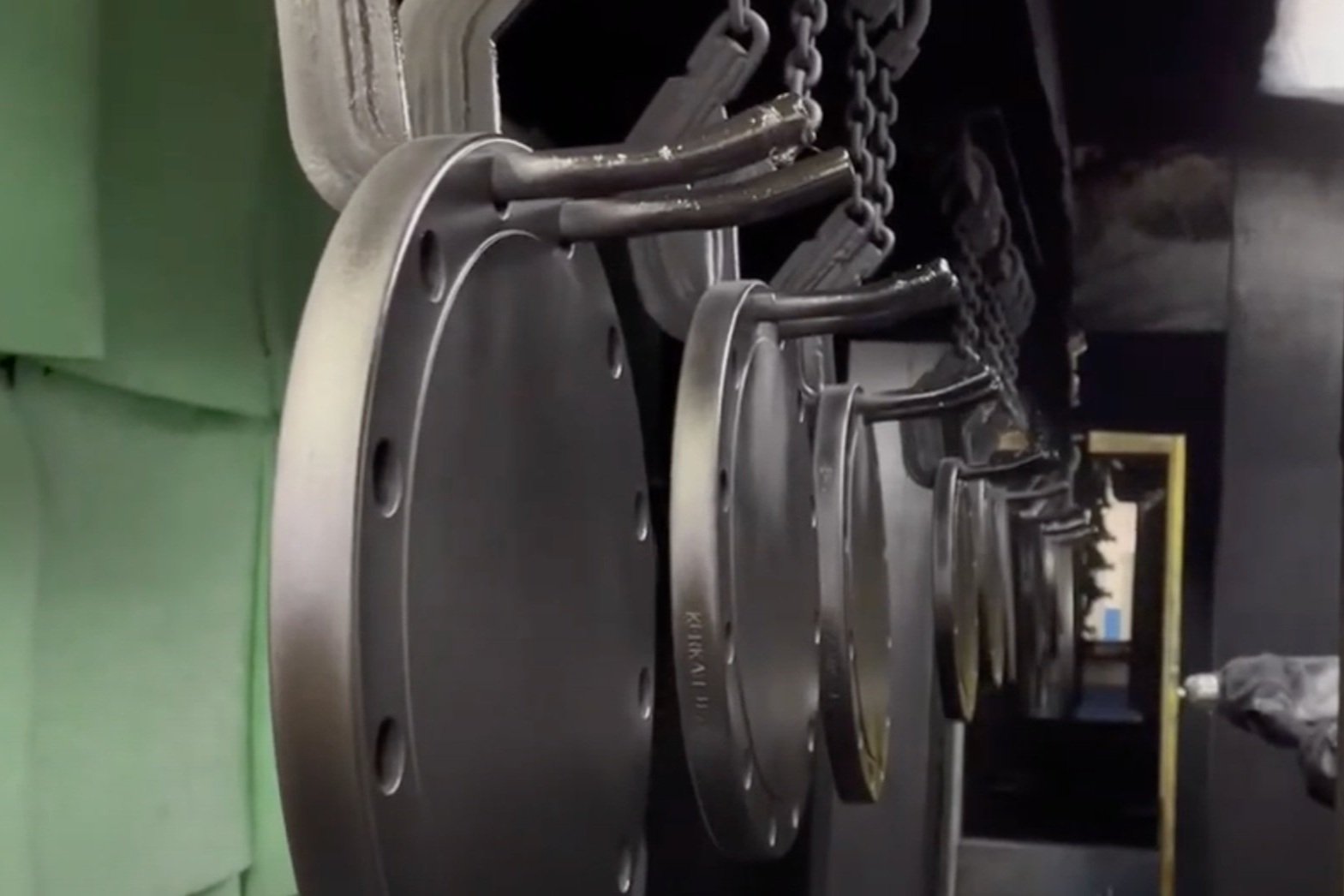

Paint System, Multi-Color, Vision Auto Part Identification

Robotic liquid paint system using Fanuc P-40 robots, Graco ProBell 2, and a custom RTSS 2D vision system to automatically offset path programming no matter what parts were loaded on the racks. Our customer experienced significant paint savings, along with both quality and throughput increases.

RTV Adhesive Bead Dispense Automation Application

RTV adhesive sealant dispense robotic application includes the following equipment: Fanuc LR Mate 200iD/7L, Graco Ultralite Dispenser, Fanuc DCS safety software, along with a variety of safety sensors. This application was designed for flexible operations, containing three part stations: an oil pan station and 2 valve cover stations. Its part detection sensors allow the operator to load however many parts are needed, and the system will automatically know which parts to work on. This system improved overall quality of the bead, achieved material savings and allowed for a more flexible workstation.

Automated Polyurea Application, Automotive Truck Aftermarket

Robotic polyurea spray application that includes the following equipment: Fanuc M-710 iC/10L, Graco HFR dispensing unit, linear shuttle with 7th axis turn table, along with all fluid distribution, controls and safety equipment. This system shuttles the aluminum part into the booth, then spins in coordinated motion with the robot to achieve appropriate spray coverage. This system was designed to improve quality of finished product, increase material savings, and provide a safer workspace for operators.

“We’re in the business of people.”

— Joe Nowowiejski, vice president

Markets We Serve

Our team's expertise encompasses many applications, delivering exceptional quality services for your projects, from initial concept to ongoing support.

RTSS seamlessly integrates with your company and project team. Our full integration approach ensures your projects are highly successful.

General Industry

Aerospace

Machine Tending

Palletizing

Packaging

Food

Customer-Centric Relationships

We enhance our customers' competitiveness and success

By being reliable, respectful and responsible.

By leveraging experience and manpower.

By executing projects with detail and efficiency.

We focus on our relationship with your team, because we know that clear communication and shared thinking are key to your projects' success. Our concerted effort approach allows us to take on projects of all sizes to build long-term success with our customers.